|

Parts List

|

||||||||||

| 1. | Spindle Nut | 2 | 11. | Long Lower Arm Spacer | 2 | 21. | GM Caliper Bracket | 2 | ||

| 2. | Outer Bearing | 2 | 12. | Spacer Gusset | 2 | |||||

| 3. | Brake Rotor | 2 | 13. | Short Lower Arm Spacer | 2 |

OPTIONAL

|

||||

| 4. | Inner Bearing | 2 | 14. | Lower Arm Mounting Bolt | 2 | 22. | Alum. Caliper Bolts | 4 | ||

| 5. | Spindle (Drop Style Shown) | 2 | 15. | Crossmember | 1 | 23. | Alum. Caliper | 2 | ||

| 6. | Caliper Bracket Bolts | 4 | 16. | Upper Spring Mounts | 2 | 24. | Alum. Caliper Bracket | 2 | ||

| 7. | Lower Shock Bolts | 2 | 17. | Upper Arm Mnting Bolts | 4 | |||||

| 8. | Standard Tubular Lower Arm | 2 | 18. | Tubular Upper Control Arm | 2 | |||||

| 9. | Shock Absorber | 2 | 19. | GM Caliper Mnting Bolts | 4 | |||||

| 10. | Coil Spring | 2 | 20. | GM Caliper | 2 | |||||

|

Installation Notes:

|

|

|

The installation of Total Cost Involved's Mustang independent front suspension unit is really very simple because Total Cost Involved has engineered all the correct angles and geometries onto the crossmember itself. All that is required are a few careful measurements to locate the crossmember and the spring mounts correctly on your chassis before welding them into position. Minor trimmings may be necessary for some variations in the frame. We recommend that all of the welding should be done by a qualified welder using the proper techniques. We also recommend that the initial and subsequent wheel alignment should be done by a qualified alignment shop. |

|

| 1. |

PREPARING THE FRAME |

| · Remove all of the old suspension and steering components and mark the axle centerline on frame. | |

| · Do not remove any crossmember except a slight trimming on the rear side of front crossmember on the '55-'59 Chevy pickup is necessary to clear the rack & pinion. | |

| · Clean the frame of any dirt/rust and weld on the supplied boxing plates. | |

| · Finish grind all welds. | |

| 2. |

INSTALLING THE CROSSMEMBER |

| · Fit the crossmember squarely an the top of the rails with the rack & pinion mount facing to the front of car. The centerline of the cross member should be inline with the axle centerline (figure #4). | |

| · The bottom of the crossmember should be parallel to the ground with the frame sitting at ride height (front and rear). | |

| · Inside measurement between frame rails should be 29". If there is any gap, this can be filled with by adding shim plates equally on both sides. | |

| · Basic location of axle centerline is given in figure #3, check your wheel base to determine your particular application. | |

| · On the '53 - '56 Ford pickup, the axle centerline may need to move forward 1-1/4" to center the wheel inside the fenders. Please check your own application. | |

| · Tack weld lower crossmember. | |

| · If you are using the Total Cost Involved's tubular lower control arms | |

| A. Drill the lower control arm holes in the crossmember to 5/8". | |

| B. Position the longer steel spacer on the rear side of the crossmember (using the lower control arm mounting bolts through the crossmember as an alignment guide) with the reinforcing gusset mounted horizontally toward the engine. | |

| C. Tack weld the spacer and gusset together and to the crossmember. | |

| · Double check all measurements including wheel base dimension and diagonally for squareness. | |

| · Final weld the crossmember to frame on all sides. | |

| 3. |

INSTALLING SPRING MOUNTS |

| · Position the spring mounts on the top, outside edges of the frame rails, with its centers directly over the center of the lower crossmember and axle centerline (figure #4). | |

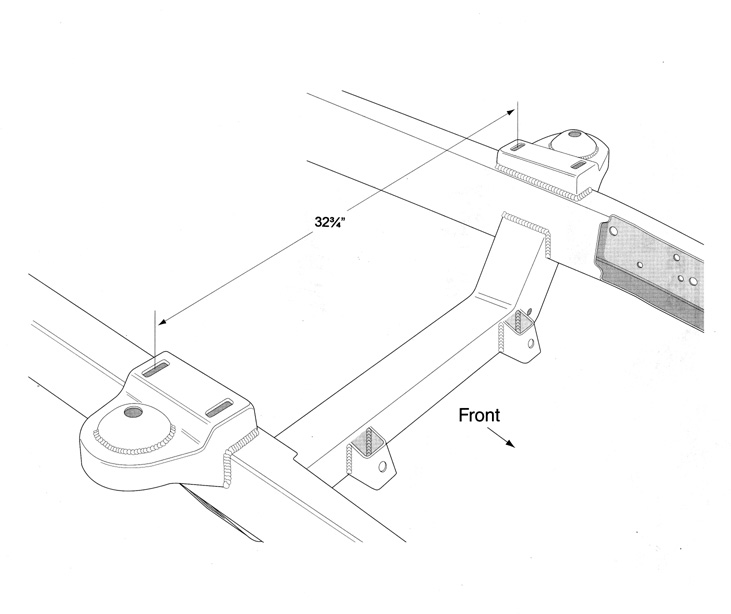

| · The distance between the middle of upper control arm adjusting slots should be around 32-3/4". Adjust the hats in or out of the frame by trimming or adding shim where the hat meets the sides of the frame. | |

| · To determine the left and right sides, the spring mounts should sit slightly lower in the rear to maintain the proper antidive geometry. | |

| · Tack both spring mounts in place, double check your measurements (also diagonally for squareness). | |

| · Mock up the upper control arm, lower control arm and the spindles, raise or lower the spindles until the lower control arm is horizontal to the ground and check the wheel camber. Make sure there is enough adjustment to set the spindle at 0º camber. | |

| · Final weld spring mounts to the frame on both sides. | |

| 4. |

COMPONENTS ASSEMBLY |

| · Install the lower control arms and strut rods, if applicable, into the crossmember. Tubular control arms should be mounted with the shock bolts toward the rear side. | |

| · Install the upper control arms, with the serrated side of the cross shaft facing down, using the special button head bolt, FORD #385713-S-101. | |

| · Install the coil springs and spindles, with the steering arms toward the front side. | |

| · Install brake rotors, calipers and brackets, rack & pinion steering unit, and shock absorbers. | |

| 5. | SUSPENSION ALIGNMENT |

| · Set ride height so the lower control arms are horizontal to the ground and align the wheel with the following specifications: | |

| Camber at 0º Caster at 1º Toe in at 1/16" | |

Figure #3

Figure #4

| All Prices subject to change without notice. |

Last Updated:

|

||

| Copyright © 2000-2003 - Zig's Street Rod Center Inc. | |||